● Personalized customization according to customer needs to ensure that the product meets market trends and user preferences.

● Use advanced design software for 3D modeling to optimize product structure and aesthetics.

Production Process

-

1. Design Stage

-

2. Order Management● Adopt an efficient ordering system to quickly and accurately handle material procurement to ensure that production materials are in place in a timely manner.

-

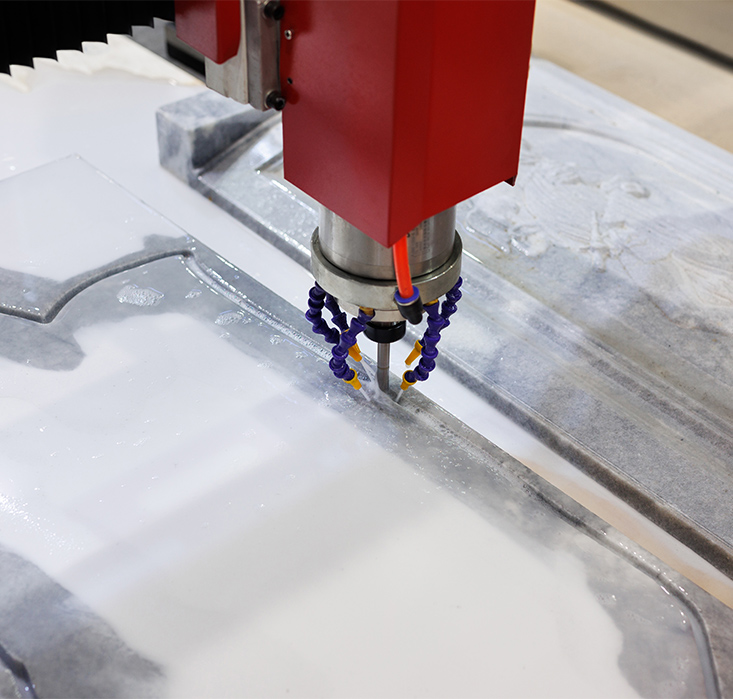

3. Cutting Process● Use high-precision equipment to cut boards to ensure that the size and shape of each piece of material meet the design requirements.

-

4. Surface Treatment● The process begins with multiple stages of grinding, progressing from rough to fine, to level the surface and eliminate scratches. This is followed by mirror polishing using specialized tools and materials to fully reveal the stone's natural veining and luster.

-

5. Automated Production● The company's fleet of over thirty specialized machines enables seamless, end-to-end production from raw blocks to finished products through advanced and reliable manufacturing processes.

-

6. Assembly Stage● Product assembly is carried out in a dedicated assembly area to ensure quality control at every link and conduct comprehensive functional testing.

-

7. Testing Link● Each product undergoes strict quality inspection after completion to ensure that it meets quality standards, including durability, appearance and function.

-

8. Cloud Transmission● Organize an efficient logistics team to ensure that products are delivered safely and promptly to the designated location of major customers.

-

9. After-Sales Service● Establish a complete after-sales service system, respond quickly to customer feedback, and provide continuous support and maintenance.